Guide to Stainless Steel Passivation - What Should You Know?

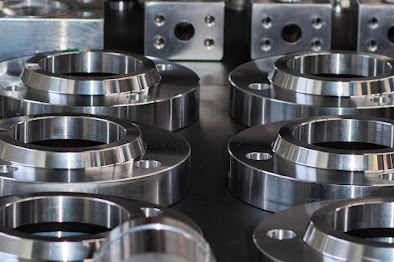

One might reasonably recommend passivation of stainless steel would not be essential. Although stainless steel is much more logically corrosion-resistant, it is not completely impermeable to corrosion. Minute suggestions of carbon and iron dropped by surface contact over any of the several manufacturing steps is what concessions the honour of the stainless-steel surface.

When these implanted ferrous impurities come into contact with water it jumps into a corrosive reaction, even in the occurrence of chromium. Stainless steel passivation services comprise the procedure of using an acid bath to eliminate free iron and other ferrous elements from the surface of stainless-steel mechanisms. Below, I’m going to share what equipment is required to passivate stainless steel portions?

What Equipment is Required to

Passivate Stainless Steel Parts?

Considering the particular

passivation service procedure to efficiently clean and acid bath passivate

stainless steel needs acquaintance and expertise. A professional is well

prepared to progress and document the process necessities to deliver constant

results.

Common passivation service procedure

stages for stainless steel:

The alkaline dusting of the supplies

to eradicate all pollutants, oils, foreign material, etc.

Water rinse - usually with tap or

deionized water

Nitric or citric acid involvement

bath to completely liquefy any free irons & sulphides and accelerate the

development of passive film or oxide layer.

Water rinse - normally with tap or

deionized water

Water rinse - normally with deionized

water

Dry parts˗ generally with a heated

compartment or centrifugal dryer

Test trial parts via specification

ideals ˗ normally copper sulphate, salt spray, or high moistness chamber

exposure challenging

What is the Machine a Professional

Uses for Passivation Services?

To confirm constant, standard

results, an expert uses a fully instinctive ultrasonic cleaner and passivation

services system. Authorized procedure parameters are encumbered into the

combined computer and saved with an exclusive identifier for each component.

Portions are loaded into the

processing unit and the washing solution; acid bath and tint cycles are

transported from holding containers into the dispensation unit through each

phase of the process. Once the automated cycle is complete the parts can be

dehydrated within the unit or in the centrifugal drier and examined.

The above-mentioned information will

help you know some important things about passivation services. You can find

one of the top companies for taking stainless steel passivation services,

zinc-nickel plating services, sandblasting services, and many others.

Comments

Post a Comment