Why Is It Necessary To Passivate Stainless Steel? How does Passivation Work?

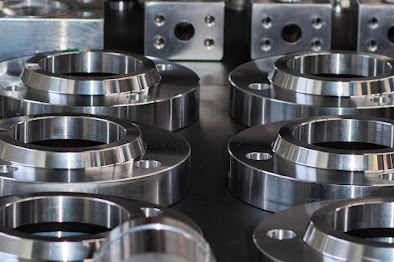

When stainless steel parts are manufactured, free iron and other matter may be left on the surface. Overtime, it’s exposed to corrosion that reduces and shortens the service life of the metal body part. Therefore, passivation of stainless steel is necessary treatment that must be performed to remove these embedded contaminants and restore to its original corrosion specifications.

Many metal parts manufacturing company and machine shop get worried and have doubts like why it is important to passivate stainless steel and how does it work? To clear all your doubt, we have answered all your queries in this post. You can also contact a reliable metal finishing company that offers you stainless steel passivation services.

Before you know why it is necessary to deactivate stainless steel, you should know what is passivation of stainless steel?

What is passivation of stainless steel?

Passivation is the most commonly used metal finishing process to prevent rust and corrosion of stainless steel. The passivation process uses nitric acid or citric acid to remove free iron present on the surface. The protective oxide layer produced by chemical treatment is unlikely to chemically react with air and cause corrosion.

As per industry standards, nitric acid, citric acid or nitric acid and sodium dichromateare used for passivation. Which method will work usually depends on the customer's requirements.

Why it is important to passivate stainless steel?

Stainless steel is a natural corrosion-resistant alloy, typically composed of iron, nickel and chromium. During the manufacturing process, through iron dust in the workshop air or in contact with carbon steel equipment, the free iron remains on the surface of the steel parts, which reduces corrosion resistance. To protect the stainless steel from rust and corrosion, passivation is very important.

How Does Passivation of Stainless Steel work?

Stainless steel is an iron-based alloy, usually made up of iron, nickel and chromium. The chromium oxide layer protects the underlying metal from interacting with the surrounding environment to form corrosion. When chromium is exposed to oxygen (air), a chromium oxide film is formed, which covers the surface of stainless steel and protects the underlying iron from rust and corrosion. The purpose of passivation is to increase and optimize the formation of the chromium oxide layer.Immersion of stainless steel in nitric acid or citric acid chemically removes free iron, leaving higher amount of chromium content on a uniform surface.

To get stainless steel passivation services at reasonable prices, you can contact a metal finishing company.

Comments

Post a Comment