5 Benefits of Black Oxide Coating You Should Know

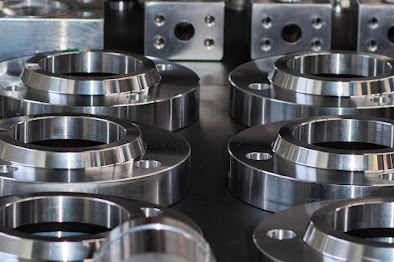

Do you know you can turn all your rusty bolts and screws into brand new through oxide coating? Black oxide coating or chemical blacking is a metal surface finish that provides increased corrosion resistance and reduced friction coefficient when in contact with other metals. When applied to screws and bolts, it's important to make sure they are compatible with a black oxide coating.

What

is black oxide coating?

When black oxide coating is applied to

screws and bolts, they must be compatible with the treatment. In addition, the

metal surface finish provides increased corrosion resistance and reduced

friction coefficient when in contact with other metals.

What

happens in black oxide coating?

When your screws and bolts are blasted with

media, it creates a porous surface. This allows the black oxide coating to

adhere directly onto the metal surface without any issues or contaminants

causing problems during application.

Black oxide treating increases corrosion

resistance in marine environments where salt is present due to its application

on steel surfaces like nuts, washers, bolts, and screws. If you own a workshop,

it’s the best kind of DIY to try. Otherwise, you can have black oxide coating services to

assist you with.

Top

5 Benefits of Black Oxide Coating

1.

Long term protection

One of the best reasons to use black oxide coating is long-term protection. This metal surface finish holds up for longer periods than other types of coatings, making it perfect in places where corrosion resistance and longevity are important factors.

2.

Low cost alternative to hard chrome plating

The black oxide coating is a low cost

alternative to hard chrome plating when it comes to protecting screws and

bolts. One of the most common uses for this metal surface finish is in highly

corrosive environments, where corrosion resistance must be at its highest level

for extended periods.

3.

Resistant to chemicals

Another great reason for using black oxide

coating is its resistance to chemical corrosion. This metal surface finish

provides excellent protection against many types of harsh chemicals, which

makes it perfect in environments where it's likely that any number of caustic

or corrosive substances could be present.

4.

Provides increased resistance to wear

Another reason for using black oxide

coating is increased resistance to wear. This metal surface finish provides the

perfect balance of low friction coefficient with excellent abrasion and

corrosion resistance. It makes it great in environments where wearing down or

corroding screws and bolts is likely.

How do I know if my screws or bolts can be

coated? Unfortunately, not all metals are compatible with a black oxide

coating, so it is important to make sure that you know which ones can be

coated. Black oxide coating works best on steel screws and bolts, but some

aluminum alloys will also work with the black oxide treatment.

How

do I apply black oxide coating?

Applying black oxide coatings requires

specialized equipment like anodizing tanks or rotary tumblers. If you're

looking for a professional, you can call readily available black oxide coating services.

Comments

Post a Comment